Connectwell - The Right Connection

Terminal Blocks

Terminal Blocks Terminal Blocks

Terminal Blocks Terminal Blocks

Terminal Blocks Terminal Blocks

Terminal Blocks Terminal Blocks

Terminal Blocks

Terminal Blocks

Terminal Blocks Terminal Blocks

Terminal Blocks Terminal Blocks

Terminal Blocks Terminal Blocks

Terminal Blocks Terminal Blocks

Terminal Blocks

In this blog, we'll explore what slim relays are, their purpose, critical

requirements in elevator control applications, the challenges faced

in building automation with a focus on elevators, the role slim relays

play in this domain, and how Connectwell Slim Relays rise to meet

the unique demands of elevator control applications.

Elevator control is a vital component of modern building

automation, ensuring seamless vertical transportation

within structures. At the heart of this intricate dance of

elevators is the often-overlooked yet crucial component -

the slim relay. In this blog, we'll explore what slim relays

are, their purpose, critical requirements in elevator control

applications, the challenges faced in building automation

with a focus on elevators, the role slim relays play in this

domain, and how Connectwell Slim Relays rise to meet the

unique demands of elevator control applications.

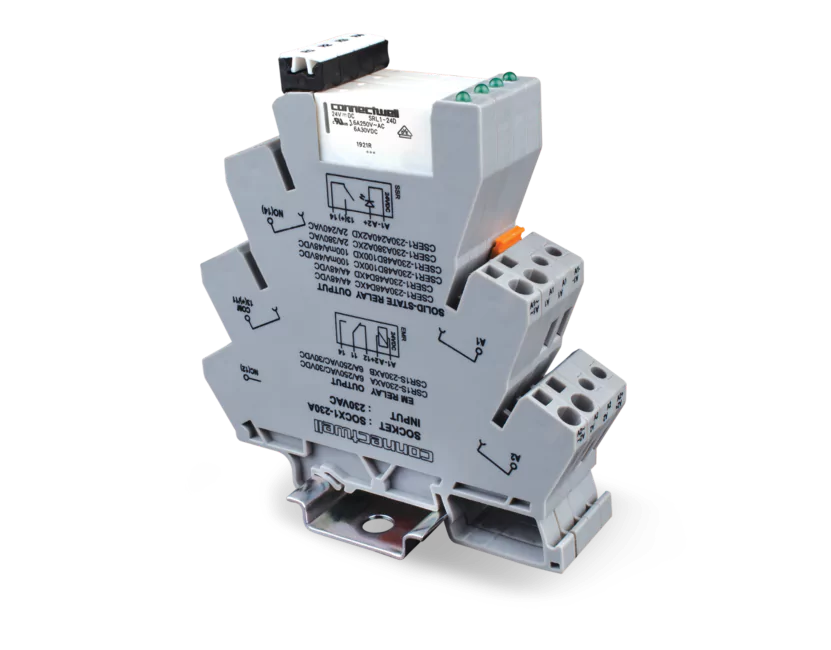

A slim relay is indeed a type of electromechanical switch, characterized by its compact design, which makes it suitable

for use in various automation and control systems where space is at a premium. Despite their small size, slim relays

are designed to be durable and reliable, offering precise control over the circuits they are connected to.

The slim profile of these relays allows them to be installed in tight spaces, making them particularly useful in densely

packed control panels or in applications where minimizing the footprint of control components is crucial. This feature

is especially beneficial in industries such as elevator control, where the efficient use of space is essential.

Slim relays typically operate by using a small electrical current to control a larger current, allowing them to act as

efficient switches in electrical circuits. They can be used to control various loads, from small signals to larger power

applications, making them versatile components in automation systems.

Their design often includes features such as LED indicators for easy status monitoring, push-in connections for quick

installation, and the ability to be mounted on DIN rails, which are standard mounting systems used in equipment racks.

Overall, slim relays are valued for their combination of compact size, reliability, and versatility, making them a popular

choice in a wide range of industrial and commercial applications

Slim relays facilitate smooth & precise control

over elevator door movements, ensuring safety

and efficiency.

Controlling the elevator motor's operation with precision, enabling smooth acceleration, deceleration, and floor alignment.

Elevator systems demand unparalleled reliability to ensure passenger safety and operational efficiency. Slim relays must provide stable performance under varying conditions.

Elevator systems demand unparalleled reliability to ensure passenger safety and operational efficiency. Slim relays must provide stable performance under varying conditions.

Elevator control systems must incorporate robust safety features. Slim relays play a role in activating emergency brakes and ensuring secure door operations.

Elevator control panels often have limited space. Slim relays, with their compact design, allow for efficient use of space within these panels.

Elevator control must respond swiftly to emergencies, demanding a reliable & instantaneously responsive system.

Coordinating multiple elevators within a building presents synchronization challenges. Slim relays play a role in ensuring smooth communication and coordination.

Elevators in buildings with unique designs may present challenges. Slim relays, with their adaptability, help address these variations in elevator control requirements.

Slim relays are pivotal in controlling the opening and closing of elevator doors with precision, ensuring safety and timely passenger embarkation and disembarkation.

Elevator motors require careful control for smooth and accurate movement. Slim relays play a key role in managing motor functions, contributing to overall operational efficiency.

In emergency scenarios, slim relays facilitate the activation of safety features, such as emergency brakes, ensuring the safety of passengers.

In the complex world of building automation, the role of slim relays in elevator control cannot be overstated. Their compact design, reliability,

and adaptability make them indispensable in ensuring smooth, safe, and efficient vertical transportation within modern structures. Connectwell

Slim Relays, with its advanced features, rise to the challenge, meeting the unique demands of elevator control applications and contributing to

the overall success of building automation systems.

With more than 15 international product certifications backed by the most stringent quality standards, our products pass through more than 40

quality assurance tests. This has ensured a ready acceptance of Connectwell terminal blocks across 80+ countries and in thousands of

projects and applications worldwide. Through our 4 decades of experience with state-of-the-art operations which are ISO certified, Connectwell

has grown to become one of the leading manufacturers of terminal blocks in the world. More than 1 million connections are made every day

across the globe with Connectwell terminal blocks, making Connectwell a synonym for… the right connection.

So, if you would like to build your projects with a solution that can accommodate both dense and simple wiring, while saving panel space,

ensure that you select Connectwell Multiple Level Terminal Blocks and get the added flexibility you need.